The Kaivac 1750 parts manual is a comprehensive guide for maintaining and repairing the machine. It provides detailed diagrams, component lists, and repair instructions for optimal functionality.

1.1 Overview of the Kaivac 1750

The Kaivac 1750 is a battery-powered, no-touch restroom cleaning machine designed for efficient and hygienic cleaning. It combines high capacity with a compact design, making it ideal for large and small spaces. The machine is known for its durability and cost-effectiveness, providing exceptional value. Its no-touch technology ensures a cleaner environment while minimizing manual effort. Suitable for various cleaning tasks, the Kaivac 1750 is a popular choice among professionals seeking reliable equipment. This overview highlights its key features and benefits, emphasizing its role as a versatile tool in maintaining cleanliness and hygiene in commercial and public spaces.

1.2 Importance of the Parts Manual

The Kaivac 1750 parts manual is crucial for ensuring proper maintenance, repair, and operation of the machine. It provides detailed diagrams, part numbers, and replacement instructions, enabling users to identify and address issues efficiently. By referring to the manual, users can extend the machine’s lifespan, prevent costly repairs, and maintain optimal performance. The manual also serves as a reference for troubleshooting common problems, ensuring minimal downtime. Overall, it is an essential resource for anyone responsible for the upkeep and functionality of the Kaivac 1750, helping to maximize its effectiveness and longevity in various cleaning environments.

Key Features of the Kaivac 1750

The Kaivac 1750 features battery-powered operation, no-touch cleaning technology, and a compact design with high capacity, making it efficient for cleaning large areas with minimal effort.

2.1 Battery-Powered Operation

The Kaivac 1750 operates efficiently using a battery-powered system, eliminating the need for cords and enhancing portability. After the first 50 hours of use, the battery life is optimized using a specific equation to ensure longevity; This feature allows for uninterrupted cleaning sessions, making it ideal for large commercial spaces. The machine’s design focuses on ease of use, with the battery contributing to its lightweight and maneuverable structure. Proper maintenance, as outlined in the parts manual, ensures the battery performs consistently, providing reliable power for extended periods. This makes the Kaivac 1750 a practical choice for high-capacity cleaning needs.

2.2 No-Touch Cleaning Technology

The Kaivac 1750 features innovative no-touch cleaning technology, enabling users to clean surfaces without direct contact. This hygienic approach minimizes the risk of contamination and ensures a more efficient cleaning process. The machine utilizes advanced water jets and cleaning solutions to remove dirt and grime effectively. By eliminating manual touch, it reduces the spread of germs, making it ideal for high-traffic areas like restrooms. The parts manual provides guidance on maintaining this system, ensuring optimal performance. Regular maintenance of the no-touch components is crucial for sustained functionality and cleanliness; This feature underscores the machine’s commitment to modern, efficient, and sanitary cleaning solutions.

2.3 Compact Design and High Capacity

The Kaivac 1750 combines a compact design with high capacity, making it ideal for efficient cleaning in various spaces. Its compact dimensions allow easy maneuverability in tight areas, while the large tank enables extended cleaning sessions without frequent refills. This balance of size and capacity ensures productivity and convenience. The machine’s lightweight frame and ergonomic design further enhance portability, reducing operator fatigue; Despite its compact size, the 1750 delivers powerful performance, making it suitable for both small and large facilities. This design ensures cost-effectiveness and efficiency, catering to diverse cleaning needs. The parts manual details how to maintain this design for optimal functionality and longevity.

Parts Manual Structure

The Kaivac 1750 parts manual is organized into clear sections, including a table of contents, detailed diagrams, and repair guides for easy navigation and reference.

3.1 Table of Contents

The table of contents in the Kaivac 1750 parts manual provides a clear and organized overview of all sections, allowing users to quickly locate specific information. It lists chapters such as machine components, maintenance procedures, troubleshooting guides, and warranty details. Each section is further divided into subsections for easy navigation. This structure ensures that users can efficiently find the information they need, whether they are looking for parts diagrams, repair instructions, or safety guidelines. The table of contents is designed to streamline the user experience, making the manual an invaluable resource for both routine maintenance and complex repairs.

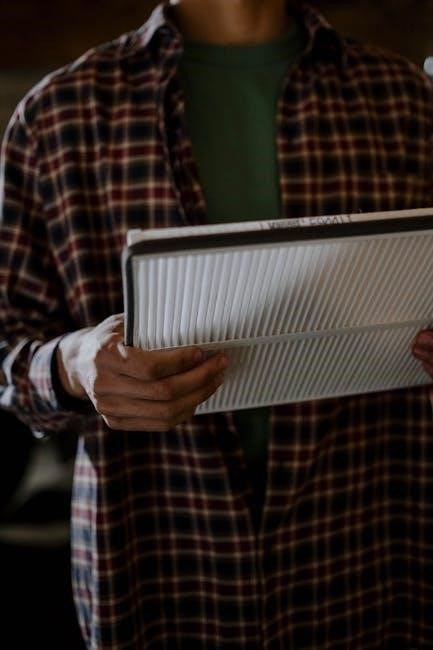

3.2 Parts Diagrams and Identification

The Kaivac 1750 parts manual includes detailed diagrams that visually identify each component of the machine. These diagrams are organized by subsystems, such as the battery compartment, cleaning head, and waste tank. Each part is labeled with a reference number, corresponding to the parts list. Users can cross-reference these numbers to locate specific components quickly. The diagrams also highlight wearable parts, such as brushes and seals, making it easier to identify items that may need replacement. This visual guide ensures accurate identification and simplifies the process of ordering replacement parts or performing repairs. The clear illustrations and numbering system make the diagrams an essential tool for maintenance and troubleshooting.

Essential Components of the Kaivac 1750

The Kaivac 1750 features essential components like the battery, cleaning head, waste tank, and control panel, each critical for efficient operation and maintenance.

4.1 Main Machine Components

The Kaivac 1750 consists of several key components essential for its operation. The battery and power system provide energy for the machine, while the cleaning head distributes cleaning solution evenly. The waste tank collects debris, and the control panel manages settings. These parts are designed for durability and ease of maintenance. Regular inspection ensures proper functionality. The battery is replaceable, and the cleaning head features adjustable jets for customized cleaning. The waste tank is made of durable materials, and the control panel includes buttons for operation and monitoring. Understanding these components is crucial for effective use and maintenance of the Kaivac 1750.

4.2 Accessories and Attachments

The Kaivac 1750 supports a variety of accessories and attachments to enhance cleaning efficiency. Optional brushes and pads can be used for different surfaces, while extension hoses allow for greater reach. Additional waste tank inserts are available for heavy-duty cleaning jobs. Squeegee blades can be replaced or upgraded for optimal water removal. Other accessories include storage carts and maintenance kits to keep the machine in top condition. These attachments are designed to customize the Kaivac 1750 for specific cleaning tasks, ensuring versatility and performance in various environments. Accessories can be ordered separately to meet the unique needs of your facility.

Safety Precautions

Always wear protective gear and follow guidelines when operating the Kaivac 1750. Avoid misuse of electrical components and ensure proper handling to prevent accidents and injuries.

5.1 General Safety Guidelines

Ensure a safe working environment by following general safety guidelines. Always wear appropriate personal protective equipment (PPE) such as gloves and safety glasses when operating or maintaining the Kaivac 1750. Keep loose clothing and long hair tied back to avoid entanglement with moving parts. Maintain good footing to prevent slips or falls. Never operate the machine in areas with standing water or near open flames. Ensure the area is well-ventilated to avoid inhalation of cleaning chemicals. Familiarize yourself with the machine’s controls and emergency stop features before use. Regularly inspect the machine for damage or wear and tear. Report any issues promptly to prevent accidents.

5.2 Handling Electrical Components

When handling electrical components of the Kaivac 1750, always disconnect the power source before performing any maintenance or repairs. Use insulated tools to prevent electric shock. Avoid touching electrical circuits or components with wet hands or while standing on conductive surfaces. Never bypass safety features or tamper with electrical systems. If a component appears damaged, do not attempt to repair it yourself; contact a certified technician. Regularly inspect battery terminals and connections for corrosion or wear. Ensure proper grounding of the machine to prevent electrical hazards. Follow the manufacturer’s guidelines for replacing electrical parts, such as batteries, to maintain safety and functionality. Always refer to the parts manual for specific instructions.

Maintenance and Repair

Regular maintenance ensures the Kaivac 1750 operates efficiently. Follow the manual’s guidelines for routine checks, repairs, and part replacements to maintain performance and longevity.

6.1 Routine Maintenance Procedures

Regular maintenance is crucial for the Kaivac 1750’s optimal performance. Ensure to clean the machine daily, checking for blockages and wear. Every 50 hours of use, inspect and lubricate moving parts. Additionally, check battery levels and charge as needed. Refer to the parts manual for specific instructions on lubrication points and replacement intervals. Always use identical parts for replacements to maintain warranty and functionality. Follow these steps to extend the lifespan and efficiency of your Kaivac 1750, ensuring it continues to deliver exceptional cleaning results with minimal downtime.

6.2 Troubleshooting Common Issues

If the Kaivac 1750 isn’t functioning properly, start by checking the battery and power connections. Ensure all components are securely attached. For clogs, inspect and clear the solution and recovery tanks. If the machine isn’t picking up solution, check the vacuum motor and hoses for blockages. Refer to the parts manual for detailed troubleshooting steps. Always turn off and unplug the machine before attempting repairs. If issues persist, contact Kaivac support for assistance. Regular maintenance can prevent many common problems, ensuring smooth operation and longevity of the machine.

Parts Replacement Guidelines

Identify wearable parts using diagrams in the manual. Use only approved Kaivac replacement parts for compatibility. Follow step-by-step instructions for safe and proper installation to ensure optimal performance.

7.1 Identifying Wearable Parts

Wearable parts are components that naturally degrade over time due to regular use. The Kaivac 1750 parts manual provides detailed diagrams and descriptions to help users identify these parts. Look for items like brushes, squeegees, and seals, which are prone to wear. The manual may use color-coding or flags to highlight these components. Regular inspection is crucial to prevent machine downtime. Use the manual’s maintenance schedule to track the lifespan of wearable parts. Replace them before they fail to ensure consistent performance and extend the machine’s lifespan. Always refer to the manual for specific identification guidelines tailored to the Kaivac 1750 model;

7.2 Steps for Replacing Parts

Replacing parts on the Kaivac 1750 requires careful planning and adherence to safety guidelines. Always disconnect the battery before starting any replacement. Use the manual to locate the part and gather necessary tools. Remove the old part by following the manual’s disassembly instructions. Install the new part by reversing the steps, ensuring it is securely fastened. Reassemble the machine and reconnect the battery. Test the machine to ensure proper operation. Use only authentic Kaivac replacement parts to maintain performance and warranty validity. Refer to the manual for specific torque specifications and alignment details. Proper replacement ensures optimal functionality and longevity of the equipment.

Warranty and Support Information

Kaivac offers a comprehensive warranty covering parts and labor for a specified period. For support, contact their team via phone or email for assistance with repairs or inquiries.

8.1 Warranty Coverage Details

The Kaivac 1750 warranty covers parts and labor for a specified period, ensuring protection against manufacturing defects. Coverage includes repairs and replacements of faulty components, excluding wear and tear. Users must register their product to activate warranty benefits. Detailed terms are outlined in the manual, including conditions and exclusions. Proper maintenance and adherence to guidelines are required to maintain warranty validity. For warranty-related inquiries, contact Kaivac support directly.

8.2 Contacting Kaivac Support

For assistance with the Kaivac 1750, users can contact Kaivac support through multiple channels. The official website provides a contact form, phone number, and email address. Support representatives are available to address inquiries, troubleshooting, and warranty-related matters. Additionally, the website offers a dedicated section for parts manuals, repair guides, and FAQs. Customers can also reach out for guidance on maintenance, repairs, or purchasing replacement parts. Ensure to have the machine’s model and serial number ready for efficient support. Kaivac’s team is committed to resolving issues promptly, ensuring minimal downtime and continued productivity.

Best Practices for Extended Lifespan

9.1 Proper Storage Conditions

Store the Kaivac 1750 in a dry, cool area to prevent damage. Avoid extreme temperatures and humidity to ensure optimal performance and longevity.

9.2 Cleaning and Lubrication Tips

Regularly clean the machine and lubricate moving parts to maintain efficiency. Follow the manual’s guidelines for recommended cleaning solutions and lubricants.

To extend the lifespan of your Kaivac 1750, store it in a dry, cool area away from direct sunlight and moisture. Ensure the machine is clean and free from debris before storage. Avoid extreme temperatures, as they can damage electrical components and batteries. If storing for an extended period, disconnect the battery and keep it in a cool, dry place. Use protective covers to prevent dust buildup. Always follow the manufacturer’s guidelines for storage to maintain optimal performance and prevent potential damage. Proper storage conditions will help preserve the machine’s functionality and ensure it remains in good working order for future use.

Regular cleaning and lubrication are essential for maintaining the Kaivac 1750’s performance. Use a soft cloth and mild detergent to wipe down exterior surfaces, avoiding harsh chemicals that could damage finishes. Lubricate moving parts, such as wheels and hinges, with a silicone-based spray to ensure smooth operation. Inspect and clean debris from brushes and vacuum pathways to prevent clogs. Apply lubricant to electrical connectors to maintain conductivity. Avoid over-lubrication, as it may attract dust. Follow a routine maintenance schedule to keep the machine in optimal condition. Proper cleaning and lubrication will extend the lifespan and ensure reliable operation of the Kaivac 1750.

The Kaivac 1750 parts manual is an invaluable resource for maintaining and repairing the machine. It ensures optimal performance, longevity, and safety, supporting effective cleaning operations.

10.1 Summary of Key Points

The Kaivac 1750 parts manual is a detailed resource essential for proper machine maintenance and repair. It outlines key components, safety guidelines, and maintenance procedures to ensure optimal performance and longevity. By following the manual, users can identify wearable parts, perform routine checks, and troubleshoot common issues effectively. The guide also emphasizes the importance of proper storage, cleaning, and lubrication to extend the machine’s lifespan. Understanding and adhering to the manual’s instructions ensures safe operation and maximizes the efficiency of the Kaivac 1750, making it a vital tool for anyone responsible for its upkeep and use in cleaning operations.

10.2 Final Tips for Effective Use

For optimal performance, always adhere to the Kaivac 1750 parts manual guidelines. Regularly inspect wearable parts and replace them as needed to prevent downtime. Follow safety precautions, especially when handling electrical components, to ensure user safety. Keep the machine clean and well-lubricated to maintain its efficiency and extend its lifespan. Store the device in a dry, cool environment to protect its battery and components. By following these tips, you can maximize the effectiveness of your Kaivac 1750 and ensure it remains a reliable tool for your cleaning operations. Consult the manual for specific instructions on replacement parts and maintenance routines.